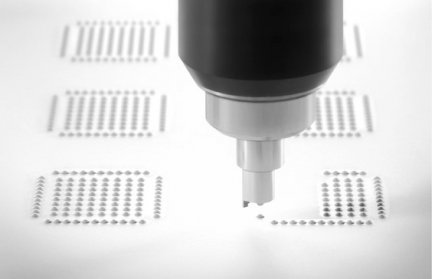

Software supported, application independent placement of components is achieved by Advanced Vision Placement.

KnowledgeInnovation and technology.

Forward-looking ideas, concept development and strategic thinking are basic elements of what we do. An active exchange takes place with universities, colleges and research institutes. We also value working with trade associations.

ReworkTechnologies for precise work.

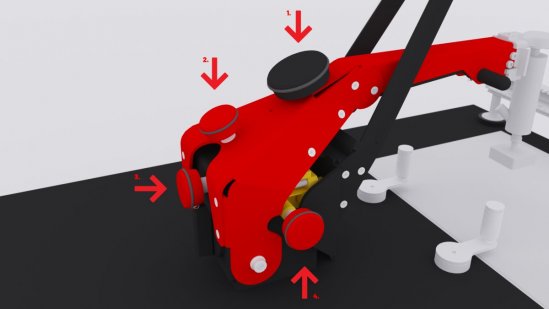

Manual camera-supported adjustment and placement of components via the MCP positioning arm. Precisely aligned to the pad structures of the PCB, it is accomplished in a user-friendly and reliable way.

The pre-bumping process can be easily and safely performed with MARTIN's pre-bumping tools. These have been specially developed for use with the MINIOVEN.

DispenseTechnologies for precise work.

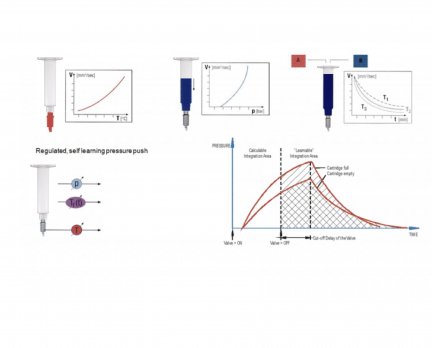

Advanced Time Pressure provides high accuracy, maintenance free and user-friendly dispensing application.

MARTIN dispense systems use stored look-up tables to compensate for viscosity variations caused by temperature changes. This results in constant dispense volumes under production environments.

Should the use of a fixed distance pin not be practical, the height sensor option can provide all the information required for accurate dispensing.

SoftwareSoftware as a carrier of innovation.

The CLEVER DISPENSE Pro software enables you to work with the dispenser with ease.

VideosProduct and application videos.

Application of Delo Photobond DM4083

Industrial research, project no. 19390N „Fadenfrei“

Institute of Joining and Welding,

Technical University Braunschweig

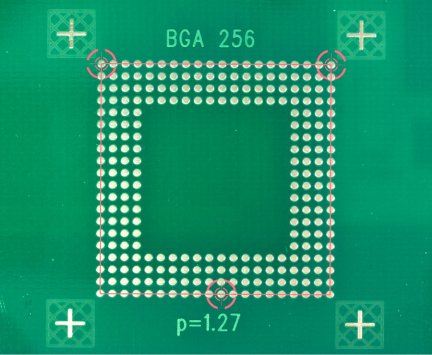

The semi-automatic Rework station with hot gas facilitates the reliable and precise rework of BGA, CSP, and QFN components, connectors, sockets, micro SMDs and more.

With the manual Rework station Expert 05.6 IXH, MARTIN offers a cost-effective solution for the complete rework process, from desoldering, pad cleaning, positioning to soldering.