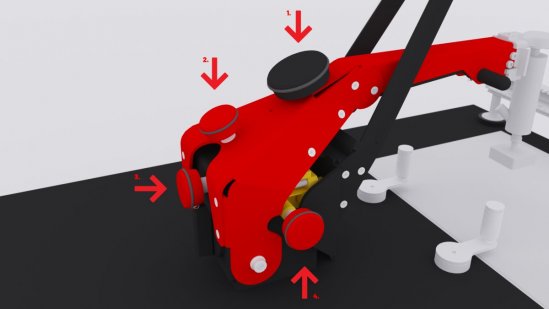

AVP stands for Advanced Vision Placement and achieves software supported, application independent placement of components.

- No adjustment of the camera lens,

- No alignment of respective camera images

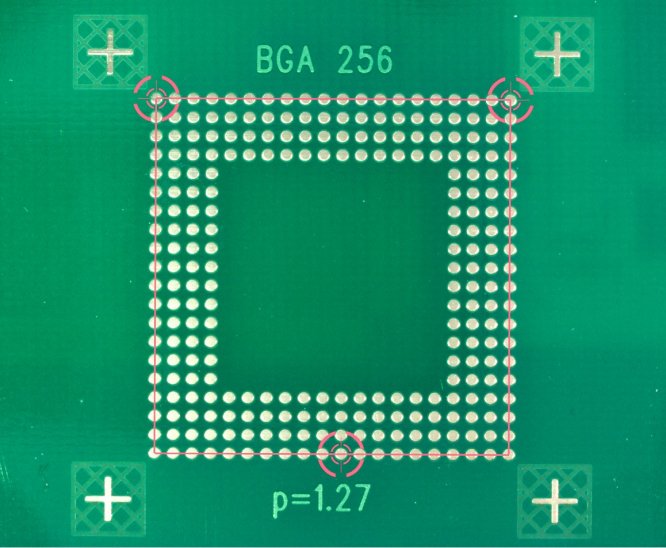

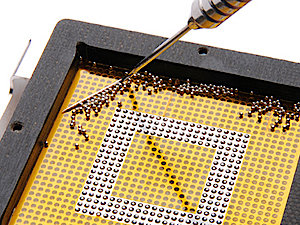

- Users merely mark the corners of the component with the mouse on the monitor image and the system takes over the automatic alignment and placement of the component

- Components are accurately placed on the PCB

- Simple automatic calibration

The patented process reduces placement errors to a minimum as the component is aligned by the high-resolution colour camera while suspended a very short distance above the board.

For the different component size ranges (µSMD->BGA or 0402 to 48 x 48 mm²) three lenses with fixed magnifications are available.