Semiautomatic rework station with gantry system for small to very large components.

ReworkPerfect solutions for the entire range of applications.

Martin offers specialized equipment for the entire range of qualifiable rework processes. All products of the EXPERT series are equipped with intuitive and touch-enabled EASYSOLDER 07 software. Components between 0.5 mm x 0.25 mm (0402) and 75 mm x 75 mm can be desoldered, placed and soldered at an accuracy of within 15 µm. With the help of APP TOOLS and the MINIOVEN 05, it is possible to prepare various component shapes for the process. Precise soldering profiles by reflow heating technology are our core competence. In combination with the devices of the Dispense series, we create a perfect environment for your projects. The camera-supported stations offer the unbeatable advantage of being able to monitor the entire process. Our unique positioning technology enables fast and extremely precise detailed work. With our stations, we guarantee perfect solutions, resource-conserving processes and reproducible results.

Independent hints about our products are provided by the guideline Rework of Electronic Assemblies by ZVEI, the german electrical and electronic manufacturers’ association.

DevicesOur Rework devices.

Semiautomatic 5,300 W hybrid Rework station for repairing large circuit boards, such as server- or mainboards.

Semiautomatic 3,300 W hybrid Rework station for repairing BGA, CSP and QFP components on medium-sized circuit boards.

Software-controlled Rework station with camera for repairing medium-sized to small circuit boards.

Combination of a 480 W hot-gas source with a vacuum pen for manual reworking of circuit boards.

High-performance 2,000 W IR under-heating system for hand soldering or preheating of medium-sized circuit boards.

Compact 500 W IR under-heating system perfectly suitable for preheating and handling small circuit boards.

Efficient 700 W contact-heat underheater for reworking small circuit boards and components.

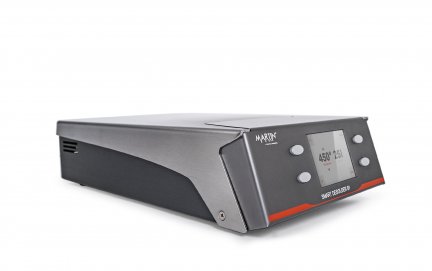

Compact hybrid device for reball and reflow processes on BGA, CSP and QFN components at the best temperature distribution.

Customers

TechnologiesOur Rework technologies for optimal results.

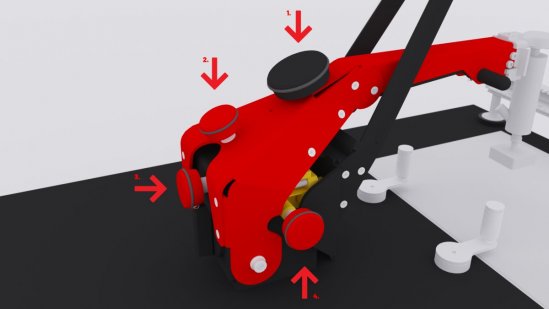

Software supported, application independent placement of components is achieved by Advanced Vision Placement.

Manual camera-supported adjustment and placement of components via the MCP positioning arm. Precisely aligned to the pad structures of the PCB, it is accomplished in a user-friendly and reliable way.

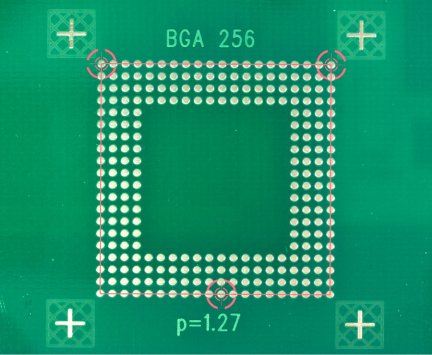

The pre-bumping process can be easily and safely performed with MARTIN's pre-bumping tools. These have been specially developed for use with the MINIOVEN.

SoftwareSoftware as a carrier of innovation.

The software EASYSOLDER 07 guides the user through the entire rework process with clarity.

VideosProduct- und application videos.

The semi-automatic Rework station with hot gas facilitates the reliable and precise rework of BGA, CSP, and QFN components, connectors, sockets, micro SMDs and more.

With the manual Rework station Expert 05.6 IXH, MARTIN offers a cost-effective solution for the complete rework process, from desoldering, pad cleaning, positioning to soldering.

Reballing with the Minioven cuts cost and lead time by not outsourcing the product.