The DOTLINER 08 is a high-precision dispensing robot suited for prototyping and small series production as well as developing tasks in the field of micro dispensing processes.

DispenseAlways on point.

The progressive miniaturization of components extends to various sectors, such as the automotive, electronics and medical technology industries. This creates ever-greater challenges when it comes to micro dispensing applications where maximum accuracy is essential. MARTIN dispensers enable flexibility in the selection of the suitable dispensing material due to viscosity independence, as well as simple processing due to highest process reliability. For the precise application of media, our volumetric dispensers deliver optimum results with high repeat accuracy. Particularly expensive dispensing materials can be used cost-efficiently. Temperature control or heating of the cartridge can be specially adapted to sensitive dispensing tasks to ensure a flawless dispensing process. With our manual to fully automatic integrable devices, we meet various requirements of the market and application areas of our customers.

DevicesPrecise and user-friendly.

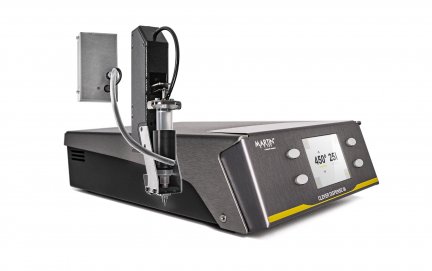

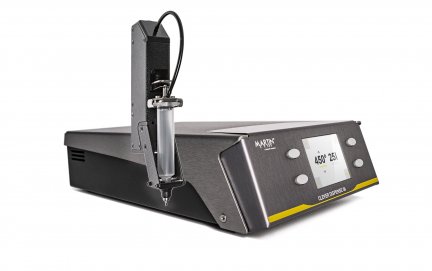

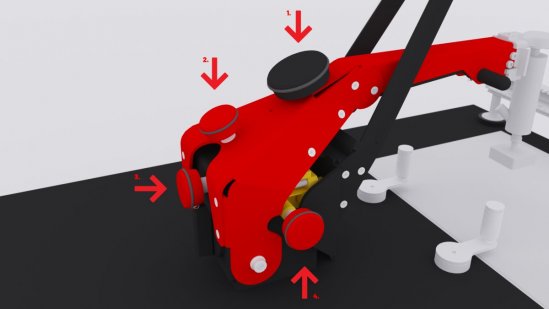

Precise dispensing device with dispensing head, plus optional tempering of cartridges and needles for integration into automation technology for volumetric handling of diverse materials.

Precise dispensing device with dispensing head, plus optional heating of cartridges and needles for integration into automation technology for volumetric handling of diverse materials.

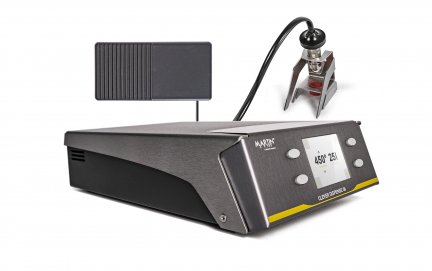

Precise dispensing device with heatable pen for manual volumetric dispensing of diverse materials.

Precise dispensing device for manual volumetric dispensing of diverse materials.

Compact and precise dispensing device with external pneumatic unit as well as optional nozzle und cartridge heater for optimal integration in automation technology.

Handy, intuitive dispensing device for manual application of pastes, adhesives and more.

Handy, intuitive dispensing device with heatable dispensing pen for manual application of pastes, adhesives and more.

Customers

TechnologiesOur Dispense technologies for optimal results

Software supported, application independent placement of components is achieved by Advanced Vision Placement.

Manual camera-supported adjustment and placement of components via the MCP positioning arm. Precisely aligned to the pad structures of the PCB, it is accomplished in a user-friendly and reliable way.

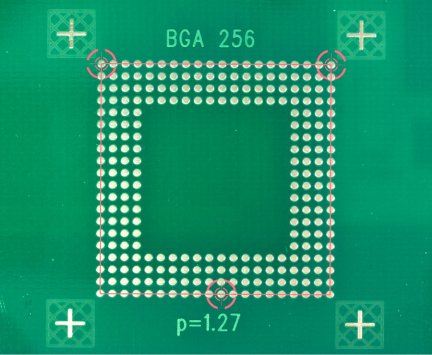

The pre-bumping process can be easily and safely performed with MARTIN's pre-bumping tools. These have been specially developed for use with the MINIOVEN.