Happy Holidays and successful start to the new year 2025.

MartinFast. Precise. Reliable.

MARTIN is a globally active company in the field of special mechanical engineering. For many years MARTIN has been developing REWORK and DISPENSE systems for customers from various industries. We offer precise, fast, handy and intuitive devices for all necessary work steps. Our product range is divided into two areas: REWORK and DISPENSE.

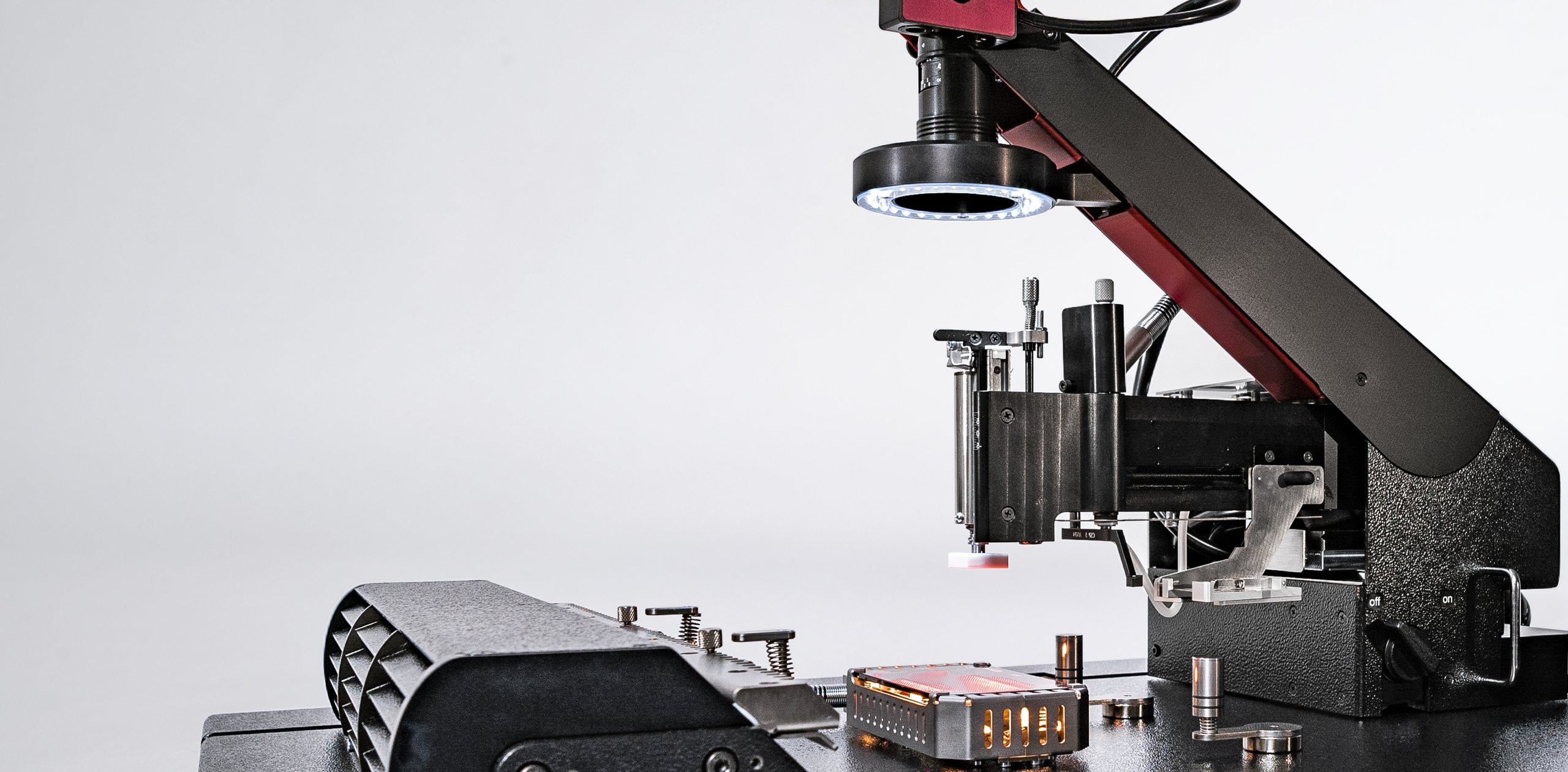

ReworkComplete solutions.

For rework and repair, we offer the right product for every step. From desoldering, removing residual solder and reballing, to placement and soldering. Our EASYSOLDER 07 software makes it possible to create precise reflow profiles for the EXPERT family and to guarantee optimum results.

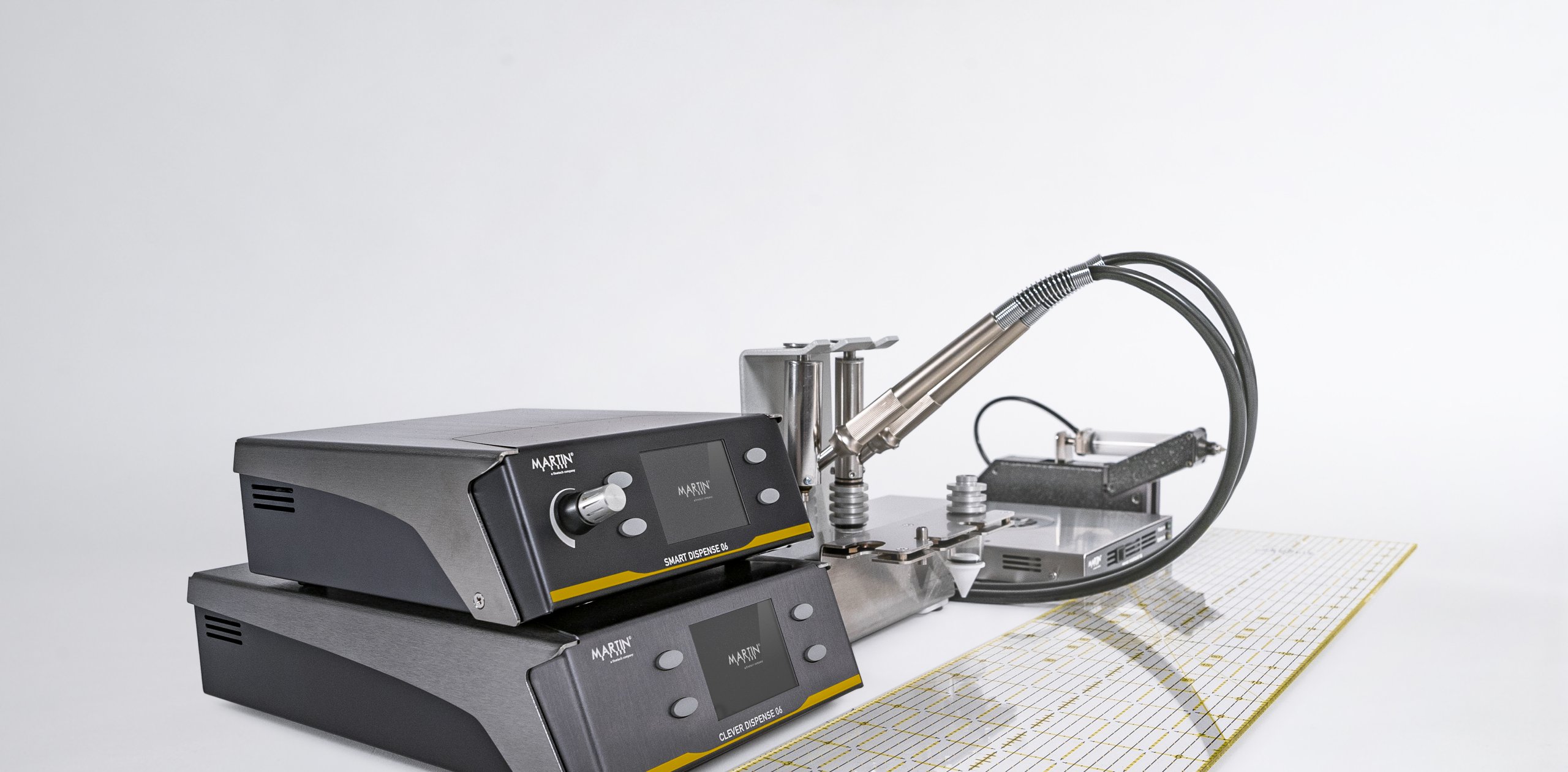

DispenseAlways on point.

Precise dispensing of liquid media is becoming increasingly important due to the ever-increasing miniaturization of components. To meet this challenge, Martin offers dispensing units for desktop and automated line production. Complete control of cartridge and dispensing nozzle temperature enables high repeat accuracy of volumetric dispensers. Expensive materials such as solder pastes, adhesives and filled materials can be processed cost-effectively. Our software makes it possible to achieve exact results immediately using the material library.

WorldwideWe are represented in 42 countries.

Industrial sectorsWe support innovation in the following industries.

SustainabilityRework conserves resources.

Professional and high-quality rework restores the correct functions of electronic components. The service life of the assembled printed circuit board is hardly impaired after the rework value chain has been carried out correctly.

Industrie 4.0Digital transformation “Made in Germany.”

Industry 4.0 involves the intelligent networking of machines and processes in industry using digital-information and communication technology. MARTIN devices are essential components in the development of modern electronic devices. Many companies working on the progressive digitalization of their production use MARTIN devices for the construction of their products. With MARTIN products you can quickly and intuitively realize your IoT vision.