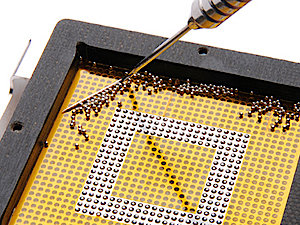

Because of the very small amounts of solder on the contacts of QFNs the use of residual solder in rework is not recommended. It is imperative that the pads of the board are cleaned; normally there is no possibility of applying new solder to them. One way of providing solder to the joints is to add it to the pads of the components. The QFNs are then reflowed to ensure that the small solder volumes are firmly attached.

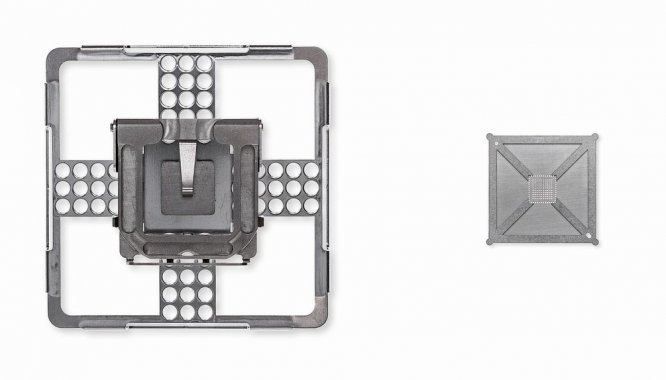

The Pre-Bumping process can be carried out easily with specific tools, specially developed for use with the MINIOVEN 05 and are available from stock for a very wide range of types of QFNs.

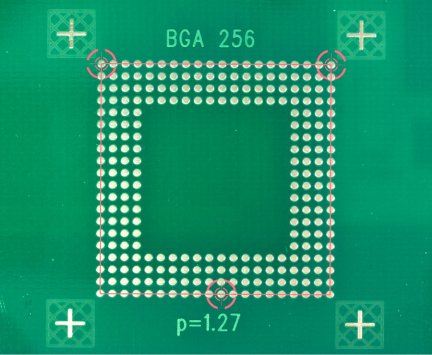

MARTIN manifactures special stencils and provides necessary solder pastes as well as other tools.

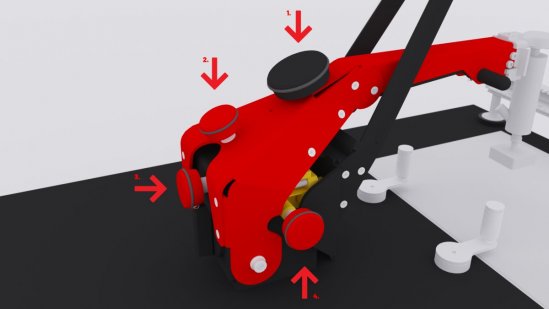

For detailed information, you can either watch the application video or contact your local representative.