Damage to the pads from overheating or mechanical stress is avoided through targeted heating of the residual solder after lifting the component. The temperature-controlled airflow prevents the neighboring components from warming up.

After melting, the residual solder is removed contactless by the vacuum pen. The use of a Teflon tip in the vacuum pen offers outstanding features: the nonstick effect, the temperature-resistance and the mechanically soft surface of the material.

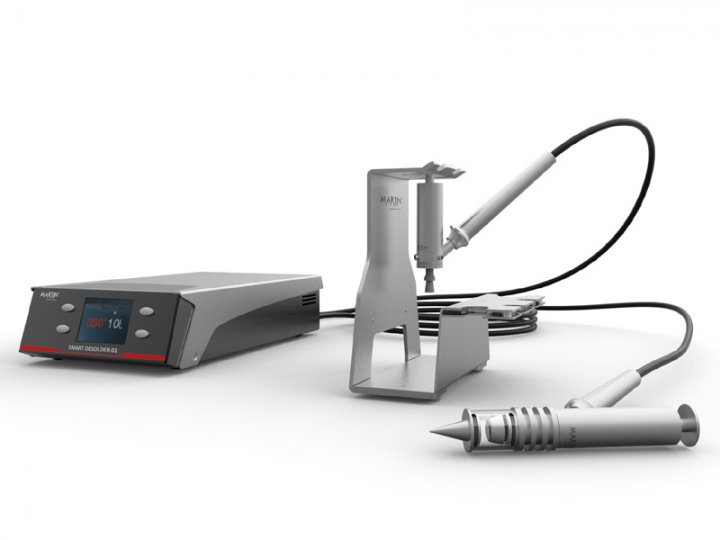

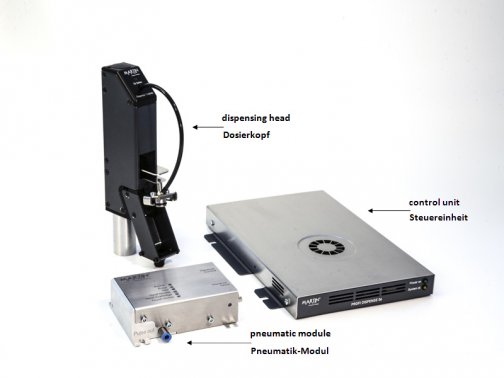

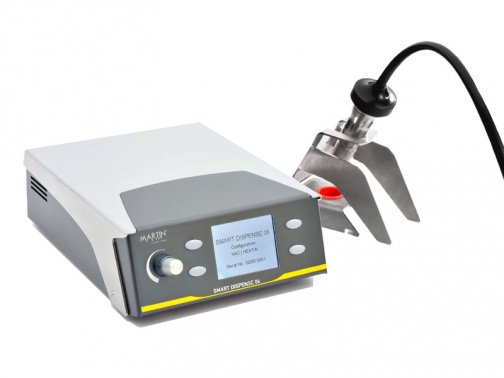

As a stand-alone device, it virtually fits on any work bench and can be operated very flexible with two handheld pens.

The bottom heaters HOTBEAM 04 or 05 perfectly complement the Smart Desolder 01. They optimize the temperature curve by means of a sensor-based or programmed preheating profile.

Smart Desolder 01 - We offer an innovative solution to gently extract residual solder

Germering, April 2017.

In the Smart Desolder 01 MARTIN combines a manual hot-gas source with a vacuum pen for noncontact extraction of residual solder.