Dispensing by Recipe

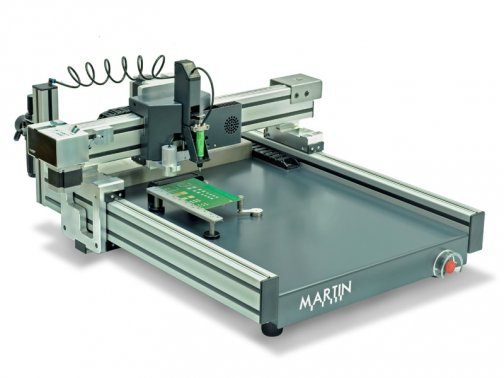

With the CLEVER DISPENSE 06 MARTIN provides a high-end dispenser. It uses well-established and unique dispensing algorithms and comes with a wide variety of additional options, concerning the temperature control of the dispensing media among other things. Combined with high-speed valves the CLEVER DISPENSE 06 can reliably produce dots and lines of size-range <100 µm.

Another new feature of the new CLEVER DISPENSE 06 is that the cartridge and dispensing nozzles can not only be cooled but also heated. Dispensing pressure and retain volume are set electronically and thus allow maximum process reliability and high user comfort. The material specifications, among other things, are stored in the electronic control. This information enables the control to compensate viscosity changes occurring from temperature variation or long dispensing time (2K media) as well as changes in filling level in real-time. The required dispensing volume is therefore kept at a constant level.

Optionally heating and cooling modules can be connected for different cartridge sizes, which allow for the media to be kept at a required temperature.

The temperature is controlled by the dispenser. Therefore, additional electronic components or software are not required.

The material specifications are stored in the material library. For well-arranged management of all information needed in a dispensing job the user applies dispensing recipes for saving process data such as dot volume, volume flow, nozzle temperature, cartridge temperature or retain vacuum.

The CLEVER DISPENSE 06 devices are equipped with useful USB, TCP/IP ports and more standard-interfaces or bus systems which enable entire control and programming. They are therefore excellently suitable for use in automation technology. Their compact design is very congenial to system integrators.

Dispensing without spilling

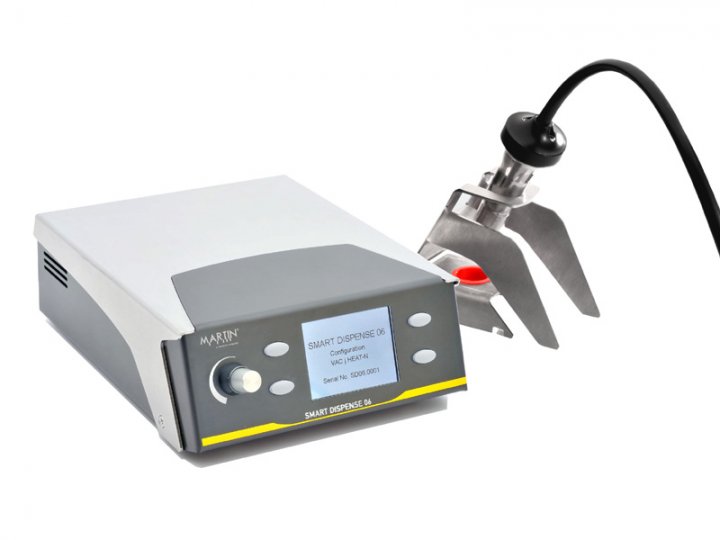

The second of the two devices, the SMART DISPENSE 06, benefits from improved control algorithms of the CLEVER DISPENSE 06. The accurate hand-held dispenser is a high-quality equipment for manual dispensing jobs that require high accuracy and repeatability. For this also, a nozzle heating and manual vacuum control is optionally available. The integrated USB interface provides for quick and transportable parameter setting.