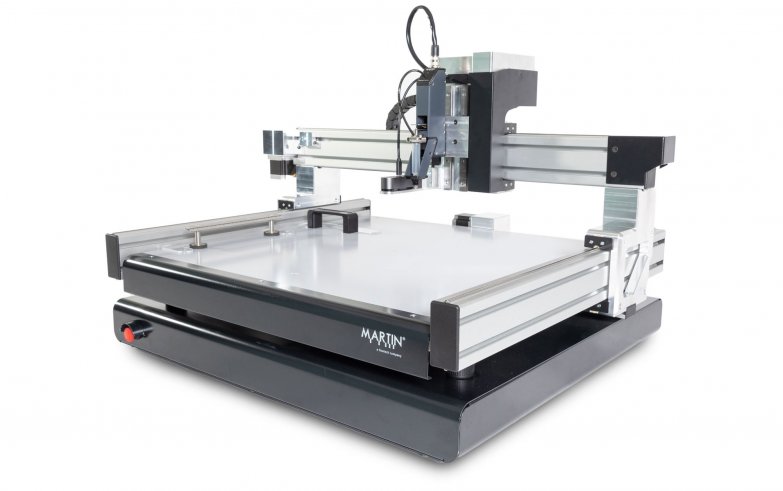

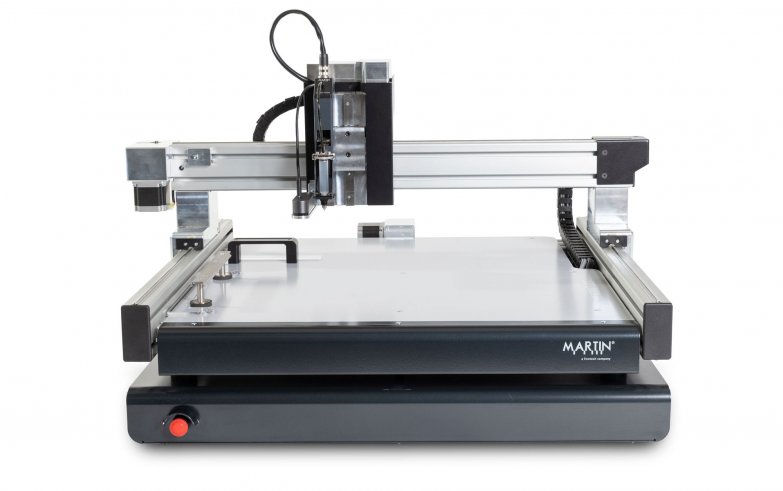

DOTLINER

The DOTLINER 08 is a high-precision dispensing robot suited for prototyping and small series production as well as developing tasks in the field of micro dispensing processes.

Top Features

DOTLINER 08

The DOTLINER 08 combines a high-precision dispenser and XYZ gantry system. Enabled by volumetric time-pressure dispensing technology, smallest volumes are dispensed as dot, line or meander shapes with highest repeatability and remain unaffected by changing environmental influences. Intuitive design, fast process changes as well as the possibility to process a wide range of different materials are characteristic features of the device. Cartridge and dispensing nozzle can be tempered independently, the dispensing nozzle is heatable as standard. This allows repeatable dispensing results due to a constant viscosity of the medium as well as the use of temperature sensitive materials. With the integration of all functions of the Clever Dispense 06, the DOTLINER 08 is the reliable partner for micro assembly, SMD rework and surface-mounting.

Product variations in the shop

| DL08.0000 | DOTLINER 08 with dispensing head 5 ccm Article Nr.: DL08.0000 |

Standard equipment

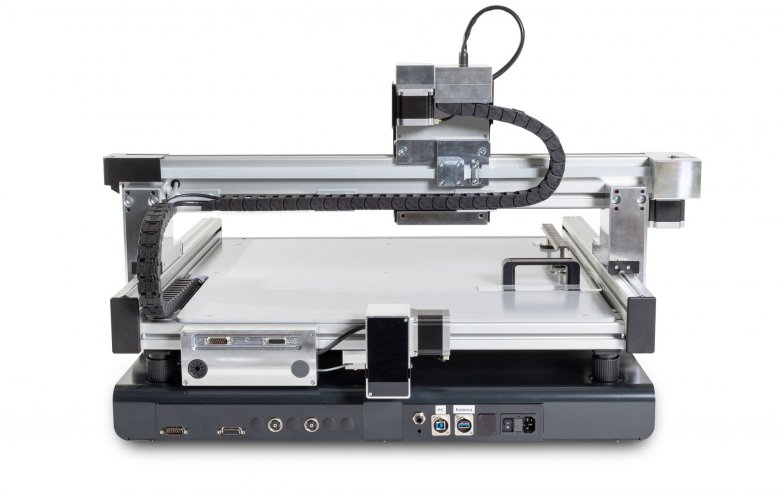

- Control unit CLEVER DISPENSE 06 with 5 ccm dispensing head

- Motorized XYZ gantry system

- Color-zoom-camera with up to 8 MP resolution

- Hight sensor for dispensing head

- 4x magnet holders for PCBs, 40.5 mm

- PCB support rail, 40.5 mm

- Test point and stand-by platform

- EASY DISPENSE 08 software

- Manual

Materials

- SMD adhesive

- Alcohol

- Silicone

- Thermal conductive adhesives

- Flux

- Solder paste

- Aqueous

- Oil

- Grease

- Underfill

- Adhesive Conductive Paste

- Sealants

Processes

- Glob Top

- Line dispensing

- Dot dispensing

- Microdispensing

- Underfill dispensing

- Adhesive bonding

- Coating

Technical details

| Max. PCB size: | 620 mm x 800 mm | |

| System accuracy: | 50 µm | |

| Travel range: | 490 mm x 420 mm x 120 mm | |

| Travel speed: | 500 mm/s | |

| Travel acceleration: | 3000 mm/s² | |

| Step resolution of axes: | 3.2 µm | |

| Dot volume: | 0.001 – 5.0 mm³ | |

| Dot diameter: | ≥ 0.1 mm | |

| Line pressure: | 0.1 – 5.0 bar | |

| Retract vacuum: | -20 mbar – 0 mbar | |

| Nozzle heating: | up to 90 °C | |

| Mains: | 230 VAC / 140 VA | |

| Pressurized air: | 5.5 - 8 bar / water and oil free | |

| Dimensions (L x W x H): | 900 mm x 790 mm x 650 mm | |

| Weight: | 70 kg |

Options

| Dispensing head: | 3, 10, 30, 55 ccm | |

| Nozzle temperature control: | from 15 K below room temperature to +50 °C | |

| Cartridge temperature control: | from 15 K below room temperature to +50 °C | |

| Underheater: | on request |

Downloads

| Product flyer | 0.8 MB | Download |

Optional extras

| DK06.0001 | Dispensing head 3ccm with nozzle heating Article Nr.: DK06.0001 | ||||||

| DK06.0002 | Dispensing head 5ccm with nozzle heating Article Nr.: DK06.0002 | ||||||

| DK06.0003 | Dispensing head 10ccm with nozzle heating Article Nr.: DK06.0003 | ||||||

| DK06.0004 | Dispensing head 30ccm with nozzle heating Article Nr.: DK06.0004 | ||||||

| DK06.0005 | Dispensing head 55ccm with nozzle heating Article Nr.: DK06.0005 |