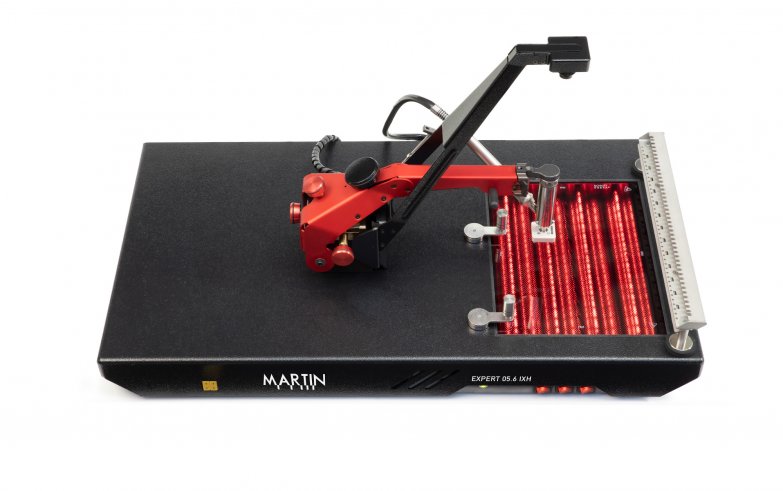

EXPERT 05.6 IXH

Software-controlled Rework station with camera for repairing medium-sized to small circuit boards.

Top FeaturesManual rework of BGA, QFP and sockets.

EXPERT 05.6 IXH

The Rework station with 2,000 W heating power in IR technology allows uniform heating over an area of 185 x 245 mm² and prevents mechanical stress due to temperature differences during the process. The high-resolution camera delivers fast, accurate and reproducible placement results. Even the smallest components from a size of 1 x 1 mm2 can be repaired and placed. User-friendly handling is provided by the touch-enabled EASYSOLDER 07 software. Reflow profiles with individual temperature parameters can be created, edited and saved and enable high process reliability and repeatable soldering. The Expert 05.6 IXH is a precise, cost-effective solution for the complete rework process on one unit.

Product variations in the shop

| HA00.5000 | EXPERT 05.6 IXH - 230 V Manual IR rework station with camera Article Nr.: HA00.5000 | ||||||

| HA00.5100 | EXPERT 05.6 IXH - 115 V Manual IR rework station with camera Article Nr.: HA00.5100 |

Standard equipment

- Two pens with magazine for soldering, residual solder removal and placing

- Solder nozzle 7 mm, BGA soldering tool 27 x 27 mm²

- Thermocouple sensor (Type K)

- Two PCB magnet holder 40.5mm (standard)

- PCB magnet holder rail 40.5mm

- Manual

- Intuitive software EASYSOLDER 07 with touch integration

Components

- BGA

- µBGA/CSP

- QFN

- DFN

- QFP

- PGA

- RF shields

- RF frames

- Rework on flex

- Small passives down to 0402

- SON

- Sockets

- Package on Package (PoP)

- Connectors & Sockets

- CPU

- Underfilled or coated components

- Film capacitor

- LED rework

- Daughter boards

- Sub assemblies

- Interposer boards

Processes

- Desoldering

- Soldering

- Solder removal

- Dipping

- Paste printing

- Reballing

Videos

With the manual Rework station Expert 05.6 IXH, MARTIN offers a cost-effective solution for the complete rework process, from desoldering, pad cleaning, positioning to soldering.

Preparing the PCB surface for the soldering process with accurate residual solder removal using the combination of a hot-gas source with a vacuum pen.

Technical details

| Power consumption: | 2,500 VA | ||||||||||||||||

| Power solder pen: | 300 W, 35 l/min | ||||||||||||||||

| Power under-heating system: | 500-2000 W | 4 x IR-lamps | |||||||||||||||

| Size under-heating system: | 185 x 245 mm² | ||||||||||||||||

| Max. PCB size: | 200 x 260 mm2 | ||||||||||||||||

| Mains: | 1Phase, 230VAC, fused 16A | ||||||||||||||||

| Pressurized air: | 5-8 bar, 100 l/min | clean, dry air | |||||||||||||||

| Airflow:: | 2-35 l/min | ||||||||||||||||

| High resolution CMOS-camera: | 1600 x 1200 Pixel, USB2 | ||||||||||||||||

| Size of component: |

| ||||||||||||||||

| Dimensions: | 660 x 360 x 390 mm3 | ||||||||||||||||

| Weight: | 35 kg | ||||||||||||||||

| * Optional extras |

Downloads

| Product flyer | 0.9 MB | Download |

Optional extras

| SF42.0301 | Tape feeder 8mm Article Nr.: SF42.0301 | ||||||

| SF44.0501 | APP Tool Pedestal Article Nr.: SF44.0501 | ||||||

| SF44.0502 | APP Tool Printer Article Nr.: SF44.0502 | ||||||

| SF44.0503 | APP Tool Basic Dipp Article Nr.: SF44.0503 | ||||||

| SF44.0504 | APP Tool µSMD Pocket Article Nr.: SF44.0504 |